Recent technology and materials advancements in fields such as aerospace, power generation and manufacturing have put more pressure than ever on inspection teams charged with maintaining massive state-of-the-art machines.

The Mentor Visual IQ™ VideoProbe™ provides operators with more features and more benefits than any previous video probe from BHGE. Its advancements, technology, and built-in connectivity can help your inspection teams significantly improve:

In addition, the Mentor Visual IQ Video Borescope provides:

- Greater ease of use for the operator

- Improved inspection quality

- Increased inspection efficiency

- Connectivity

- Collaboration tools to easily share data

Configurations

The Mentor Visual iQ combines the portability you want with the powerful processing you need. Available configurations include:

Mentor Visual iQ Analyze:

On-demand 3D Phased Measurement and analysis software combined with extreme image quality for increased probability of detection (PoD).

Mentor Visual iQ Touch:

A highly capable borescope designed for extreme inspection productivity with Quick Change(TM) probes, touch-screen interface, on-device workflow management and reporting, and 16GB of internal memory.

Mentor Visual iQ Inspect:

A value-priced inspection offering with best-in-class image quality, streamlined user interface, and Wi-Fi and Bluetooth connectivity.

*Each Mentor Visual iQ Video Borescope configuration can be upgraded in the future.

Key Features and Benefits

As traditional Measurement Technologies become less adaptable and effective in the modern world, the need for an RVI tool that delivers an accurate assessment for all applications is crucial.

For that reason, the Mentor Visual iQ VideoProbe has been designed to provide a host of benefits for modern inspection teams.

A large, high-quality display: Integrated 6.5” active matrix, color LCD display is easy to read in daylight and low-light situations. A touchscreen is available on Analyze and Touch models.

High-output LED lighting: For illuminating dark areas during inspection.

State-of-the-art electronics: New hardware ensures the Mentor Visual iQ line will have consistent upgrade options moving forward.

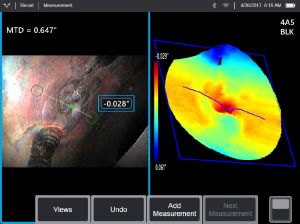

3 D phase measurement: Patented structured-light technology enables inspectors to locate, measure and analyze without having to change tip optics.

D phase measurement: Patented structured-light technology enables inspectors to locate, measure and analyze without having to change tip optics.

3D stereo measurement: Uses the same optical tips as traditional stereo measurement—but employs more advanced calibration and processing algorithms to generate a full, 3D point cloud representation of the surface being viewed.

3D point cloud visualizations: View a live, 3-dimensional point cloud representation of the object being inspected.

Interchangeable probe sizes: Multiple probe sizes available to meet different types of inspection requirements.

A variety of tips available: Choose the tip that best match your field-of-view and depth-of-field requirements.

Highly accurate measurements: Indications can be measured in real–time from the Mentor Visual iQ VideoProbe —and re-measured on a computer later on, without having to relocate the indication.

Connectivity: Wi-Fi options allow you to beam live video from the probe’s screen anywhere in the world, enabling you to quickly share data about an inspection.

InspectionWorks ready: Optional InspectionWorks connectivity allows experts to view a live inspection in progress from across the globe, allowing smarter decisions, faster.

Menu Directed Inspection (MDI): MDI software in 14 languages digitally guides inspectors through the inspection process, intelligently names files and creates MS Word® and PDF compatible inspection reports.

Durability: Designed for use in today’s demanding manufacturing, aerospace, and power-generation environments.

Light, compact and easy to carry: Weighing less than 9 pounds, the video probe is portable and built for extended use.

Remote control: Hands-free operation available through the optional remote control.

Windows file management: On-board, Windows-based file management makes it easy to transfer files.

Easy data transfer: Files can be transferred by removable memory card, USB connection, or through the unit’s on-board Wi-Fi connectivity.

Made and supported in the USA: The Mentor Visual iQ VideoProbe is manufactured in the U.S.A. and supported by Berg Engineering and Baker Hughes, a GE company.

Industries

With advancements in technology and materials, a versatile, adaptable, technology-driven tool for remote visual inspection is increasingly important across many industries.

The Mentor Visual iQ VideoProbe is ideally suited to meet the needs of these industries:

Aerospace:

- Extreme image quality and lighting enhances probability of detection (PoD) in all engine stages

- Measurement surface scanning and analysis for fast and accurate go/no-go decisions

- Collaboration tools let you easily share inspection analysis with remote experts to significantly reduce AOG and inspection time

Power generation:

- Handheld portability makes inspections in difficult access areas faster and easier

- User-defined profile setups accommodate specific inspector preferences or inspections by plant type

- Durable design for rugged inspection conditions

Manufacturing:

- Faster, more accurate inspections for pumps, motors, generators, pulp and paper rollers, gear boxes, pipes, tubes, purity pipes, compressors, large pistons, chillers, valves, gun barrels, mortar tubes and maritime surveying.

- Quick-change probes with multiple lengths and diameters allow for more inspection areas with a single system

Efficiency, Quality, Versatility

As a professional inspector, your job is to keep the machines running, the planes flying, and the energy flowing.

The Mentor Visual iQ VideoProbe delivers the technology, accessibility, and connectivity you need to make better decisions about maintaining your machines—faster.

Company Background

Berg Engineering and Sales Company Inc. has been servicing the industrial industry since 1969. We provide sales and full service to the NDT (non-destructive testing), material testing, and electrical testing equipment industries.

The testing equipment manufacturers we represent are global leaders in technology-driven inspection solutions to help improve customer cost, productivity and quality of their products.

Our company has maintained customer relationships for over forty years. Berg Engineering also has a large rental fleet of equipment to help best serve our clients.

- On-site training

- Free support

- Factory trained and certified by BHGE

- Preventative maintenance